How to Build Window Cornices

Updated: Jan. 17, 2019Custom-build your own window cornices for one-fourth the price of store-bought

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $51–100

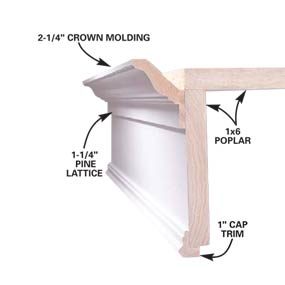

Design the cornice to fit your home

Design elements within your home should dictate the wood type, molding style and finish that you select. Depending on the design, the top either overlaps the sides, sometimes with a routed edge, or is nailed to the top or inside of the box and doesn’t show from below. The tops are best made from 1x4s, 1x6s or 1x8s. There’s no need to cut the tops to width if you choose the right combination of top style and board size. The example we show is a 1×6 nailed on top of the box, which gives an overall inside depth of 4-3/4 in. For the same look but with a shallower box, you could also nail a 1×4 inside the box flush with the top for a depth of 3-1/2 in. Choose whichever method it takes to clear your curtains.

Other Cornice Design Options

A Cornices design options are almost endless. If you’re having trouble choosing, here’s a tip. Buy short lengths of different types of trim along with some cheap 1x4s and 1x6s. Cut everything to 1-ft. lengths and mock up several different combinations. Just squirt a little wood glue on the pieces and clamp them together for about 10 minutes. Hold the cornice mock-ups over the opening to get a feel for the final look.

Select materials and collect key tools

If you plan to paint your cornices, poplar and aspen are good choices for the box materials. They’re stable and cheap, and the grain won’t show through paint. Pine and basswood moldings are usually the least expensive choices for paintable trim.

If you want stained or natural wood cornices, look for oak, mahogany, cherry, maple and others at home centers. The biggest problem is finding hardwood moldings other than oak. You may have to special-order them or find a specialty millwork supplier online.

The best tool for cutting miters on wide boards (1x6s) is either a 10-in. compound miter saw or a sliding compound saw. Standard compound saws work like typical miter saws, but the motor and blade tip sideways, making them capable of cutting bevels. A sliding compound miter saw cuts compound angles too, but the motor and blade slide on tracks so it can handle wider stock.

Be sure to use a sharp finish-cutting blade in either one. Prices for standard compound miter saws are quite low, or you can rent one.

You can predrill and hand-nail most of the project, but an air-powered brad nailer with 1 and1-1/2-in. brads makes the job much easier. Many are inexpensive and well worth the price. Or you can rent one. (Rent one of the special airless ones and you’ll save the price of renting a compressor.) But for the money, compound miter saws and brad nailers are far too useful and far too fun not to own yourself.

Assemble the basic box

Every wood cornice begins the same way, with cutting and assembling the three-sided, lidded box (Photos 2 – 4). Then you add the trim of your choice (Photos 5 – 9) and finish the cornice (Photo 11). The cornice is then ready for mounting on the wall by screwing it to a 1×2 that’s screwed to the wall above the opening (Photos 12 – 14).

Begin by measuring the curtain and curtain rod for length, depth and width (Photo 1). Measure with the curtains open so you take into account their thickness when bunched. Add an inch or so to the depth and the width of the curtain rod to make sure the cornices will cover everything.

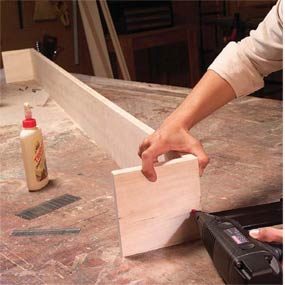

Miter the ends and front box pieces first. It’s easiest to square up the board, then tilt the miter saw to cut a 45-degree bevel for the first end piece and then square it up to cut the second end (Photo 2). The mitered corners are glued and nailed together with 1-in. brads. Measure the assembly to determine the exact length for the top.

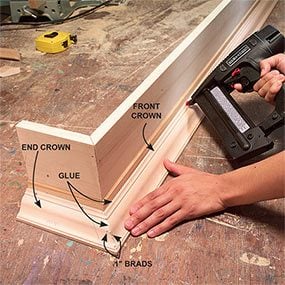

Apply the trim

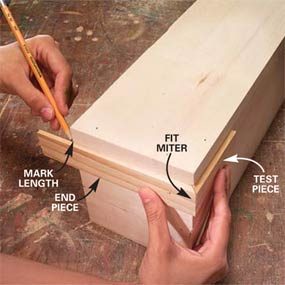

When mitering the trim for the box, always start by first cutting and mounting an end trim piece, then the long front trim and finally the other end. That way, you’ll be able to check fits and get crisp miters at each corner. Fit each miter, then scribe the length of each piece rather than measuring (Photo 5). It’s faster and much more accurate. It’s best to cut pieces just a tad long so you can shave them down until they fit perfectly. If you’ re new to woodworking, it’ s nice to have a helper by your side to hold the miters together while you’re scribing lengths or fastening parts.

The trick to cutting perfect crown molding miters is to rest the molding upside down and against the bed and fence while cutting the 45-degree angles (Photo 6). If you cut wide crown molding, you may have to extend the fence height by screwing a length of 1×4 to the miter saw fence through the holes in the back. Remember that the long point of the miter is always the top edge. That’ll help you remember which way to angle the saw before cutting. To further eliminate the costly mistake of miscutting, an angle, draw a light line while you’re fitting the piece to indicate the proper angle (Photo 6).

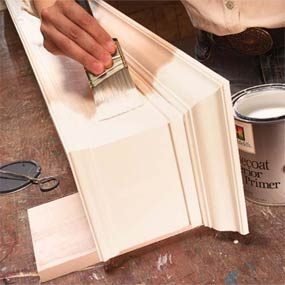

Smooth and finish cornices

Fill nail holes and prime before painting. If your cornices have elaborate details like dentil blocking, you’ll get better results with several light coats of spray paint instead of brushing. Finish highly detailed natural and stained wood with spray lacquer, shellac or polyurethane.

Prepaint the 1×2 cornice ledger to match the wall before you put it up if you think it’ll show after the window covering is in place (Photo 13).

Mount the cornice over the window

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Air Powered Brad Nail Gun

- Cordless drill override and 1/8-in. bit.

- File

- Miter saw

- Paintbrush

- Safety glasses

- Screw gun

- Tape measure

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 2-1/2-in. wood screws

- Glue

- Paint or stain

- Sandpaper (fine)

- Wood filler