Wood Deck vs Composite Deck: Which One Is Right for You?

Need help choosing deck boards? We've got you covered.

Whether you’re building a new deck or replacing old, worn boards, you’ll find an overwhelming number of decking options. The two main categories, wood and composite, include dozens of choices. I’ll walk you through the most popular ones to help you choose the right material for your deck.

On This Page

Types of Wood Decking

Wood decking is beautiful and typically much more economical than composite. However, after a few years it loses its warm tone and turns a dull gray if it’s not meticulously maintained. That increases its lifetime cost.

Pressure Treated Wood

- The boards are soaked with chemicals and put under pressure so the treatment permeates the entire board. That makes them resistant to rot and insects.

- Copper, a common element in treatments, gives treated boards their green tint.

- When you’re sanding or cutting any treated lumber, respirators are a must.

- This lumber is readily available in many red and brown tones.

- Cut ends of pressure-treated boards must be treated with an exterior sealer, such as Woodlife CopperCoat.

- Boards must be thoroughly dry before you apply a stain or protective finish.

Cedar Wood

- Naturally rot- and insect-resistant.

- It has a beautiful bright tone and can be stained easily.

- Long lasting and easy to work with.

Exotic Wood: Ipe, Cumaru

- Naturally rot- and insect-resistant, exotic woods have a beautiful, high-end look.

- The installation is labor intensive. The boards are heavy and dense, and need to be predrilled for screws.

- The boards are available with or without grooved edges to accommodate hidden fasteners.

PVC Decking

Cellular PVC is an all-plastic decking. Its core is a porous (cellular) lightweight plastic that’s capped just like other composite decking. PVC contains no organic material to rot, grow mold or swell when exposed to moisture, and it comes with a 20-plus-year warranty from staining and fading.

- Can be bent using heat for stunning curved designs. PVC expands and contracts more than wood and WPC as the temperature shifts.

- It may become stained with exposure to some rubber products like grill mats and water shoes.

- PVC is the most expensive option, ranging from $4.40 to $7.50 per linear foot.

Wood Plastic Composite Decking

Made with up to 95 percent recycled plastic that encapsulates the wood fibers, wood plastic composite (WPC) decking is strong and often comes with a 20-year or longer warranty against staining and fading. Unlike natural wood, it won’t crack or splinter. Aside from an easy annual soap-and-water cleaning, it’s pretty much maintenance-free decking.

- Much heavier than wood.

- Some WPC decking requires shorter joist and stringer spans because it’s less rigid than solid wood.

- Ranging from $2.90 to $6 per lin. ft., WPC is more expensive than wood.

Mineral-Based Composite

Mineral-based composite (MBC) is the newest type of composite decking. It’s as lightweight as PVC but twice as strong, and carries a 25-year stain and fade warranty. There’s virtually no temperature-induced shrinking or swelling. MBC decking is highly resistant to moisture.

- MBC is more rigid than WPC and PVC, so it can be used on longer joist and stringer spans.

- It can withstand ground and water contact.

- It can maintain smaller gaps at miters and seams. Ranging from $4 to $6 per lin. ft., MBC is comparable in price to WPC.

Capped Vs. Uncapped Decking

Most modern decking has a hard plastic cap for better protection against harmful UV rays, weathering, scratches and dents. Capped deck boards provide color variations and the appearance of textured wood grain. But uncapped decking has improved and still has a place.

Uncapped boards are cheaper and available with wood grain patterns. Because uncapped deck boards are uniform throughout, you can round over cut ends or edges with a router without noticeably changing the board’s sheen or color. Scratches or dents can be “healed” with a heat gun or left to heal naturally over time under the sun’s heat.

How Much Does It Cost to Build a Deck?

You can find economical, midrange and high-end choices for each type of decking. A typical deck (16 x 20 ft.) covers about 350 sq. ft. For that size, the cost of decking alone can range from $450 to $2,700.

Design Options

Today, it’s easy to get the look you’re after. The color, grain pattern, size and shape of the boards give you countless design options.

Deck Grain Pattern

Every board of natural wood has a unique grain pattern. Even though the “grain” in composite decking mimics real wood, the pattern repeats from board to board. The grain options vary, from a deep embossed texture to tight, straight grain.

Get A Grip

Although all decking meets a minimum requirement for grip, if you’re concerned about slippery conditions, consider decking with deeper grain.

Color

Almost any tone of wood or stained wood is available in composite decking. In addition, some of the more expensive composites have realistic color streaking that mimics the natural colors of real wood. Typically, you won’t see this in the more economical options, but you’ll still find a wide range of colors.

Temperature

Composite decking gets hot in the sun. So if your deck gets full sun, consider lighter-colored deck boards or be prepared to wear shoes. Some manufacturers claim their decking has special properties that resist heat retention, remaining cooler even in darker colors.

Common Deck Profiles

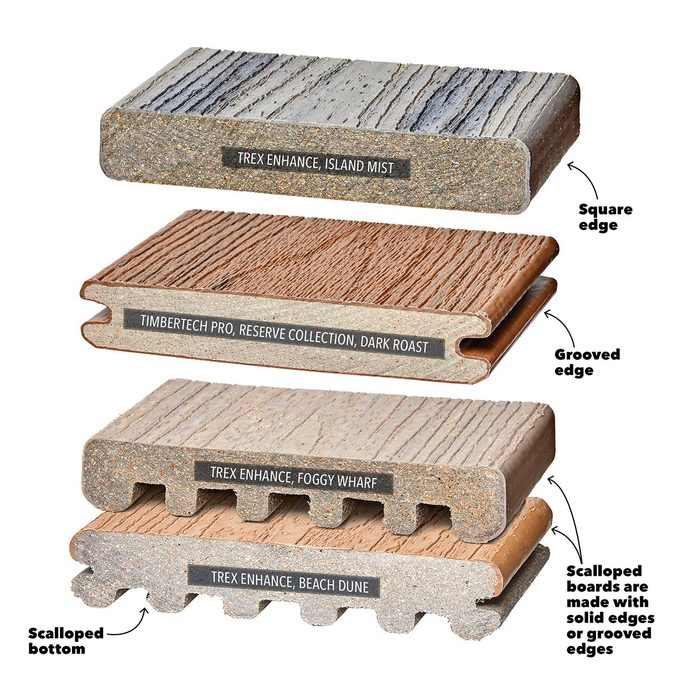

The profile and cross section of your deck boards may seem insignificant, but they’re important to how your deck is built and how it will look.

Square Edge

Use square profile boards on your deck’s borders to hide cut ends or as a pattern board to avoid seams. With square profile boards, you’ll typically drive fasteners through the face of the boards. However, some fastening systems let you hide the fasteners by using a jig to drive them into the board’s edge at an angle. CAMO has a system like this.

Grooved Edge

Use grooved-edge boards in the middle of the deck, anywhere the edge isn’t visible. Hidden deck fasteners fit in the grooves for a clean look.

Scalloped Bottom

The scalloped undersides make the board lighter weight and a little less expensive. Face-screwing scalloped boards can be difficult. Screws angle toward the grooves, pull the board and leave an oblong hole that’s hard to plug.

Non-Standard Board Widths

Standard deck boards are 5-1/4-in. wide, but many companies offer different widths, from three inches up to almost 12 inches wide. This lets you achieve a different look from standard decking and opens the door to many design possibilities. Wide boards also make single-board stair treads possible.

Follow Fastener Recommendations

Whichever decking you choose, be sure to follow the manufacturer’s fastening instructions. The warranty typically depends on your use of the recommended fasteners, including face screws, fascia screws and hidden fasteners.

Matching Skirt Boards

Most decking manufacturers offer a 1/2-in.-thick version of decking for use as skirt boards (11 inches wide) and stair risers (eight inches wide). These are typically available in a manufacturer’s color options.