How to Build an Outdoor Storage Bench

Updated: Feb. 27, 2023Buy PDF & Cut List At first glance, this bench may look like a complex project. But take a closer look and you’ll see that the structure couldn’t be more basic

- Time

- Complexity

- Cost

- A full day

- Intermediate

- $101–250

Materials List

- 70’ of 1×4 pine (this us a minimum amount; we bought 100’ and selected sections)

- 4’ x 8’ of 3/8” BC grade plywood

- 1-5/8” galvanized drywall screws

- 1-1/4” galvanized drywall screws

- 8 x 1” pan head screws

- 1-1/4” galvanized nails

- 5/16” staples

- 3-1/2” galvanized hinges

- Exterior wood glue

- Lid support

- Spray adhesive

- Weather stripping (adhesive-backed foam or rubber)

- Plastic or rubber foot pads

Cutting List

Outdoor storage bench waterproof tech art

Build it from 1x4s and plywood

The wood and hardware for our bench cost about $120. Upholstery supplies can cost $50 to $150, depending on what you select (see “Choosing Upholstery”).

We built our bench from pine 1x4s. Using a rot-resistant wood like cedar, redwood or teak will more than double the lumber cost. Top-grade pine is expensive too. We used lower-grade pine instead, bought extra material and “harvested” the knot-free sections for the visible bench parts. We used some of the leftovers for the slats (G) that form the floor inside the bench. The upholstered seat and panels are all cut from a single sheet of 3/8-in. BC-grade plywood.

You’ll need a table saw, jigsaw, a sander and a drill to complete this project. A router and chamfer bit are optional (see photo 5). You’ll also need a pocket-hole jig (Photo 2) or a biscuit joiner to assemble the frames.

Cut curved rails

Each of the four frames that form the box is made from four parts: The vertical frame parts, or “stiles” (C, D), are simply pieces of 1×4 cut to length. The horizontal frame parts, or “rails” (B, E), are ripped to the correct width on a table saw. The Cutting List provides all the dimensions.

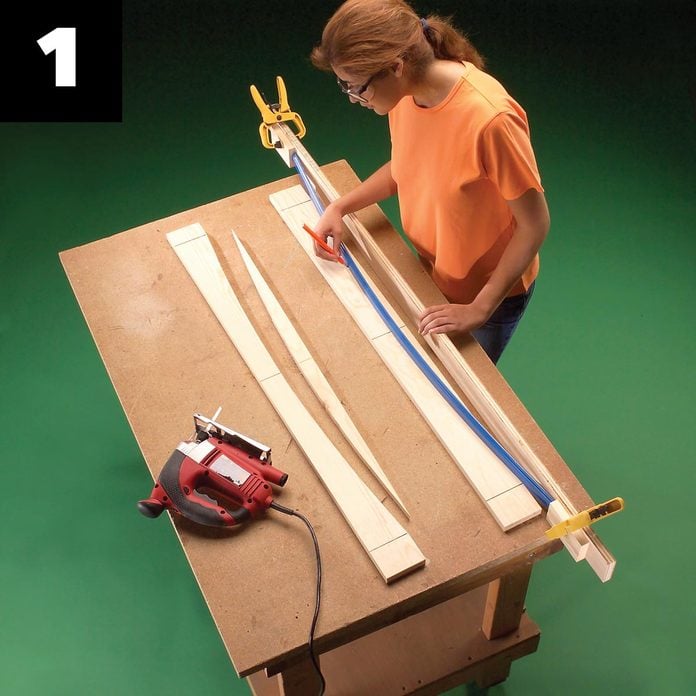

Don’t cut the curved rails (A) to their final length until the curves are cut and sanded. Instead, start with boards at least 41 in. long. Mark them as shown in Figure B and Photo 1. Plastic doorstop molding ($3 at home centers) works great in an arc jig, but any thin, knot-free strip of wood will do.

Take your time as you cut the arc with a jigsaw. Don’t worry if the cut is a bit wavy. You can smooth it out with a random orbital sander or finish sander and 100-grit sandpaper. If you move the sander back and forth across the entire arc using even speed and pressure, minor waves will gradually even out.

Assemble frames with pocket screws

You could assemble the frames using biscuits or dowels, but we chose pocket screws because they’re fast, easy to master and nearly foolproof. Here’s how they work: A stepped drill bit – guided by a jig – bores into the wood at a steep angle to create a pocket (Photo 2). Then you simply place a screw in the pocket and drive it into the adjoining piece (Photo 2).

In addition to pocket screws, use exterior wood glue such as Tightbond II or Tightbond III to strengthen joints. When you assemble the side frames, be sure to position the stiles (D) 3/4-in. from the outer ends of the rails (E). Allow the glue to set for a couple of hours, then sand each frame with an orbital sander.

Join the frames and add slats to complete the box

Before you join the frames to form the box, fasten cleats (F) to the lower front and back rails (B). The frames that form the box are fastened together only with 1-5/8-in. screws at the corners (Photo 3), so the box isn’t very strong until you add the legs later (Photo 6). Handle the box carefully if you need to move it.

The slats (G) not only form the floor of the box but also hold it square. Take diagonal measurements as you install the slats – equal measurements mean the box is square (Photo 4). You have only about five minutes before the glue begins to set, so it’s best to have a helper hold the box square as you work. You’ll have to rip the final slat on your table saw to fit.

Add the legs

Each leg is made from two parts (H and J) glued together. The final length of the legs is 18 in., but start with pieces that are at least 1/2-in. longer. That way, you don’t have to perfectly align the ends when you glue and clamp them together. Scrape away excess glue and let the glue set for at least an hour before removing the clamps. Sand the legs and cut them to length. For a decorative option, we chamfered the three edges of each leg (Photo 5). Use eight 1-1/4 in. screws (four on each side) and glue to fasten ech leg to the box (Photo 6).

Make the seat from two layers of plywood

You could cut the seat (M) from a single piece of 3/4-in. plywood, but we glued two layers together (Photo 7) for two reasons: First, this trick allowed us to buy only a single sheet of 3/8-in. plywood. Second, it gave us a flatter seat. Single plywood sheets are often bowed. By gluing two sheets together (with both bows facing in or out) the bows cancel each other and you end up with a flat sheet. Start with sheets cut about an inch oversize and then cut the seats to final size after gluing. Drill eight 1/2-in. holes in the seat so air can escape from under the upholstery when someone sits on it. Using your jigsaw, round the corners of the seat to about the radius as a nickel. To protect against moisture, we painted both the plywood seat and the panels before upholstering them.

Fastening hinges to the seat is a lot easier before the seat is upholstered (Photo 8). Remove the hinges to upholster the seat and finish the outdoor storage bench seat. With the screw holes established, remounting the hinges later is foolproof.

Choosing upholstery

Craft and fabric stores may carry some outdoor upholstery, but for the best selection and advice, start with an upholstery store. Outdoor fabric costs about $6 to $30 per yard. With batting and foam added, expect your total bill to be at least $45. The standard width of upholstery fabric is 54 in. You’ll need a piece at least 90 in. long and an equal amount of batting. We used 1-in.-thick, medium-density foam. Many suppliers will cut the foam to size for you (29 x 57 in.) Here are three things to keep in mind while choosing fabric:

- Most outdoor fabrics are vinyl, but a few other materials are available. Make sure the fabric you choose is waterproof and easy to clean. This will make your outdoor storage bench waterproof.

- Tell the salesperson how and where your outdoor storage bench seat will be used. Some vinyl can crack on cold weather or degrade in direct sunlight.

- Solid colors or subtle patterns are easiest to work with. Stripes are the most difficult.

Upholster the seat

Here’s the best thing about simple upholstery work: Most mistakes are no big deal. All you have to do to correct them is pry out the staples and try again.

Cut the fabric, batting and foam to size (see Cutting List) and lay them on your workbench. The foam is easy to cut with scissors or a utility knife. Take the seat outside and coat one side with spray adhesive. Position the seat carefully as you set it on the foam; it will bond immediately and you won’t be able to reposition it. Photos 9-12 show the upholstery process. Here are some pointers:

- Start by tacking the fabric at the middle of all four sides (Photo 11). If your fabric has a pattern, flip the seat over to make sure the pattern is properly aligned.

- Work outward from the idle of one side, then go to the other side and stretch the fabric as you work outward. Tug gently – the fabric doesn’t have to be stretched super-tight.

- Stop occasionally and flip the seat over to see if you’re creating ripples in the fabric. Usually you can make ripples disappear by prying out a few staples and stretching the fabric more or less.

- Stop stapling about 3 in. from each corner and deal with the corners only after all four sides are done.

- Cut out “V” sections of fabric at corners to avoid creating a thick lump of excess fabric (Photo 12). Start by cutting out a small “V” and enlarge it if necessary.

- If your fabric is a stiff vinyl that won’t conform well at corners, heat it with a hair dryer to soften it.

Final touches on the outdoor storage bench seat

With the bench stained and the panels covered, screw the panels inside the frames (Photo 10). To keep the legs off the wet patio or deck, screw on 3/4-in. plastic feet. Even with the seat closed, a little rainwater can seep around the upper edge. We also added a lid support to hold the seat open.

If you store furniture cushions in the bench, you’ll create a paradise for mice. To keep them out, staple 1/4-in. galvanized hardware cloth to the underside of the slats. The most important thing you can do to preserve your bench is to maintain the finish. Since the panels and seat are removable, adding a fresh coat of paint or stain is easy. Finally, and most critical of all, if you have children around, don’t store yard chemicals inside the bench.

Mark a curve on upper rails using the arc jig. Cut the curve with a jigsaw. Don’t cut the rails to their final length until you’ve sanded the curve.

Clamp each joint to a flat surface and add the pocket screws. Be careful not to drive screws too deep in soft wood.

Glue and nail bottom cleats to the front and back frames. Then predrill and fasten the four frames together with 1-5/8-in. screws.

Glue and nail the slats in place, using 1/4-in. spacers to position them. Take diagonal measurements to make sure the box is square.

Cut 1/4-in. deep decorative chamfers in the legs with a router. Stop the chamfers 2-1/2 in. from the ends.

Glue and screw the legs to the corners of the box from the inside. Predrill 1/8-in. clearance so the screws can draw the legs tight against the frames.

Glue two layers of 3/8-in. plywood together to make the seat. Drive screws every 6 in. through both layers into straight 2x4s and remove the screws after the glue sets.

Fasten the hinges to the box first. Then lay the seat on the floor and position each hinge as shown. Remove the seat to upholster it.

Staple batting to the panels. Then attach the fabric with staples around the perimeter. Trim off the excess batting and fabric with a utility knife.

Screw the panels inside the frames with 1-in. pan head screws spaced every 6 in.

Lay out the fabric, batting and foam. Lightly coat the plywood seat with spray adhesive and center it on the foam. Staple the fabric to the plywood, starting at the middle of each side and working toward the corners.

Create small gathers in the fabric, starting about 3 in. from corners. Cut out “V” sections on both sides of the corner. Then fold the fabric inward, pull the corner back and staple.