Fountain: How to Build a Concrete Fountain

Updated: Feb. 23, 2023Carving stone requires years of training, extraordinary skill and endless patience—or you can cheat and use power tools.

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $101–250

Overview

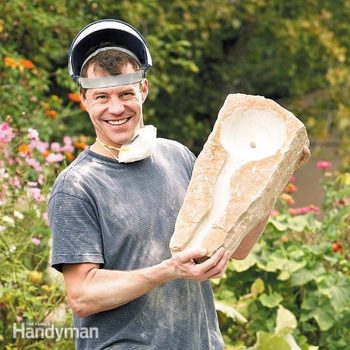

If you have a circular saw and an angle grinder, you can spend about an hour in a cloud of dust and emerge with a carved fountain stone like this one. You won’t need any special talent, just a few tricks and a couple of diamond saw blades (see “Tools and gear” below).

A weekend is plenty of time to carve the stone and create a small pond. Your masterpiece could look entirely different from the one I made, depending on the shape of the stone you choose. I purchased all the stone and spent about $200 on the whole project, but if you have access to free stone, you can cut that cost in half.

Selecting a stone

The 6-in.-thick sandstone block I used was about 9 x 20 in. and cost about $15 at a landscape supplier. The stone you use can be any size and shape as long as it has a flat spot that’s at least 8-1/2 in. across. The bowl itself will measure just over 6-3/4 in. across and 2 in. deep.

Soft stone is best for this project. Although you can cut and grind very hard stone, it could turn this one-hour task into an all-day chore. Also avoid stone with strong “grain”—layers of harder and softer stone—because it tends to crack along the layers. That makes chisel work risky; one wrong blow can ruin your project.

Hardness and grain aren’t always obvious from look and touch. So if you pick up stone alongside the road, you won’t know if it’s workable until you try it. If you buy stone, be sure to ask for recommendations. In most areas, sandstone and some types of limestone are your best bet.

Getting started

Cutting stone whips up a dust storm—don’t even think about doing it in your garage. Work as far away as possible from anything you don’t want coated with dust, especially open windows or your neighbor’s convertible. Take five minutes to set up a sturdy work surface (I used a couple of sawhorses and 2×8 planks.) You’ll get better results if you’re working comfortably, and you’ll save your back. If the stone wobbles on your work surface, steady it with shims.

Next, mark out the bowl and channel (Photo 1). If you want a curving channel like ours, avoid tight curves; anything tighter than the curve of a 1-gallon paint can will be tough to cut with your grinder. Make the channel about 1-1/2 in. wide and flare it to a width of 2-1/2 in. at the bowl. The flare helps create strong water flow. The flare at the front of the channel is purely for looks.

Building the Fountain

This pond is small—a 30 x 36-in. oval, about 14 in. deep. Building a pond couldn’t be much simpler. Just dig a hole, line it with pond underlayment followed by an EPDM rubber liner and surround it with stone. Then build a simple stepped-up wall to support the fountain stone. Here are some tips for a smooth project:

- Select larger flagstones for the first layer surrounding the pond. They stay put better and can overhang the edge of the hole by 2 to 3 in. to hide the liner.

- Leave a small gap between two of the flagstones so you can feed the pump tubing through later.

- The flagstone I used for the wall had flat faces that fit together fairly tightly when stacked. That allowed me to glue them together with polyurethane construction adhesive (see Photo 8). If you use irregular stone, you’ll have bigger gaps and mortar would be a better choice. If you use large stones, you may not need adhesive or mortar. Heavy stones stay put by themselves.

- The pump I used is rated for 210 gallons per hour. A smaller pump may have worked, but I’ve learned that it’s better to spend a little extra than to discover later that a pump was too small.

- Even if your pump has a built-in flow adjustment knob, consider adding a valve (see Figure B) for quicker, more accurate adjustments.

- Choose your tubing before you drill the hole in the bowl (Photo 7). Depending on the outer diameter of the tube, you need either a 5/8-in. or 3/4-in. drill bit.

- The tubing I used fit snugly into a 3/4-in. hole. So I slathered the tube with silicone caulk, slid it about 1-1/2 in. into the stone and let it set overnight. Don’t insert the tube all the way to the top of the drilled hole. The larger diameter of the drilled hole helps to dampen water pulsation caused by the pump.

Cut, chisel and grind the bowl

Fire up your saw and make the bowl cuts (Photo 2). When making plunge cuts, you have to keep an eye on both the front and the back ends of the blade to make sure you don’t cut beyond the circle. And remember that the spinning blade will try to drag the saw backward. If your circle disappears under a layer of dust, stop and blow off the dust. If you guesstimate where the line is and guess wrong, you’ll end up with a lopsided bowl. Make at least eight cuts; the more cuts you make, the easier the next step will be.

Next, chisel out the bowl (Photo 3). If any of the slices don’t break out easily, rev up your saw again. Better to make more cuts than to whack out a big slice and leave a crater in the bowl. Grinding (Photo 4) is tedious, but patience pays off in the form of a smooth, rounded bowl. With very soft stone, like the sandstone I used, you can polish the bowl even smoother by hand-sanding with 80-grit sandpaper.

Cut the channel

Cut the channel as deep as the diamond blade on your grinder will reach (about 7/8 in., depending on your grinder). But the key to controlling that spinning blade is to make all cuts in shallow passes (1/8 to 1/4 in.). Start by cutting the outer edges of the channel. Don’t worry about forming perfectly smooth curves yet; if you have to form a rough curve with a series of short, straight cuts, that’s OK. Next, cut grooves in the middle of the channel (Photo 5). Then chisel out the channel (Photo 6). That will open up space to smooth out the curved edges with the diamond blade, a grinding disc or a combination of both. When the channel is done, drill a hole in the bowl (Photo 7) sized to accept the tube from the pump.

Set the fountain stone

Positioning the stone takes some care. You have to adjust the flow from the pump, level and shim the stone from side to side so water doesn’t spill out of the bowl, and tilt the stone slightly for a strong, spilling stream. When you have it right, remove the stone, apply a bed of mortar or generous beads of construction adhesive, and reset the stone. Keep the 2×4 bridge in place overnight. If water clings to the underside of the stone and runs back toward the stone wall, apply a bead of clear silicone caulk under the front of the stone. The silicone “drip edge” will force the water to drop off.

Tools and Gear

- To cut the bowl, you’ll need a standard circular saw and a 7-in. diamond blade. Diamond blades can cost $75 or more. But for this small job, cheaper is better. I spent about $30.

- To smooth the bowl, you’ll need a small angle grinder and a grinding wheel. Don’t balk at buying a grinder just for this project; you’ll find other uses for it. If you want to cut a curved channel, you’ll need a 4- or 4-1/2-in. diamond blade. Or you can cut a straight channel with your circular saw.

- I used a hammer drill to drill the hole in the bowl. But a standard drill, along with a little extra patience, will do the job if you’re using soft stone. Use a masonry drill bit diameter that matches the outer diameter of the pump tubing.

- This project whips up a tornado of dust and grit, making a dust mask and eye protection mandatory. Safety glasses will do, but I prefer a face shield. Those flying slivers of stone sting!

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Angle grinder

- Caulk gun

- Circular saw

- Cold chisel

- Dust mask

- Hammer drill

- Hearing protection

- Level

- Safety glasses

- Spade

- Utility knife

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 2x4 x 8

- 80-grit sandpaper

- Ball valve

- Barbed fittings

- Brick

- Corrugated tubing

- EPDM rubber liner

- Flagstone

- Hose clamps

- Mortar

- Polyurethane adhesive

- Pond pump

- Shims

- Silicone caulk

- Underlayment